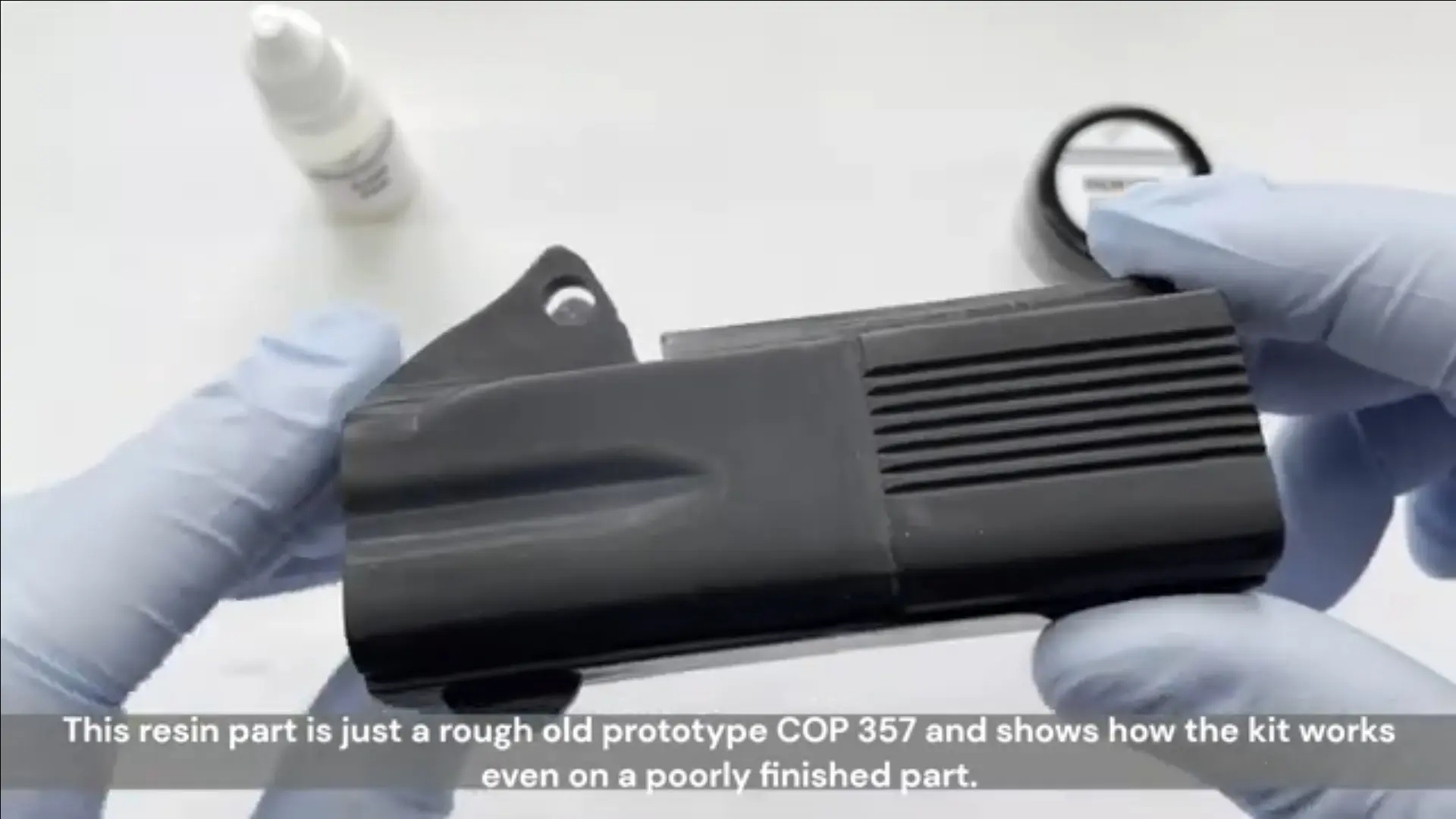

3D Printed Part Prior To Paste Application

Start With The 3D Printed Part Preparation

As with traditional painting techniques the quality of the final result is dependant on the finish of the part.

The kit is very forgiving in the surface quality of the part but if you want a nice shiny blued finish the resin part must be sanded and polished before applying the paste.

The usual method of sanding the part with progressively finer sandpaper or wet & dry still applies here.

With resin you may find all you need are the following grades of sanding paper: 600, 800, 1000, 2000. A high gloss finish may require higher grades up to 5000.

The image shows a part that has been polished to give a pretty good surface shine but way more time could have been spent to improve on this.

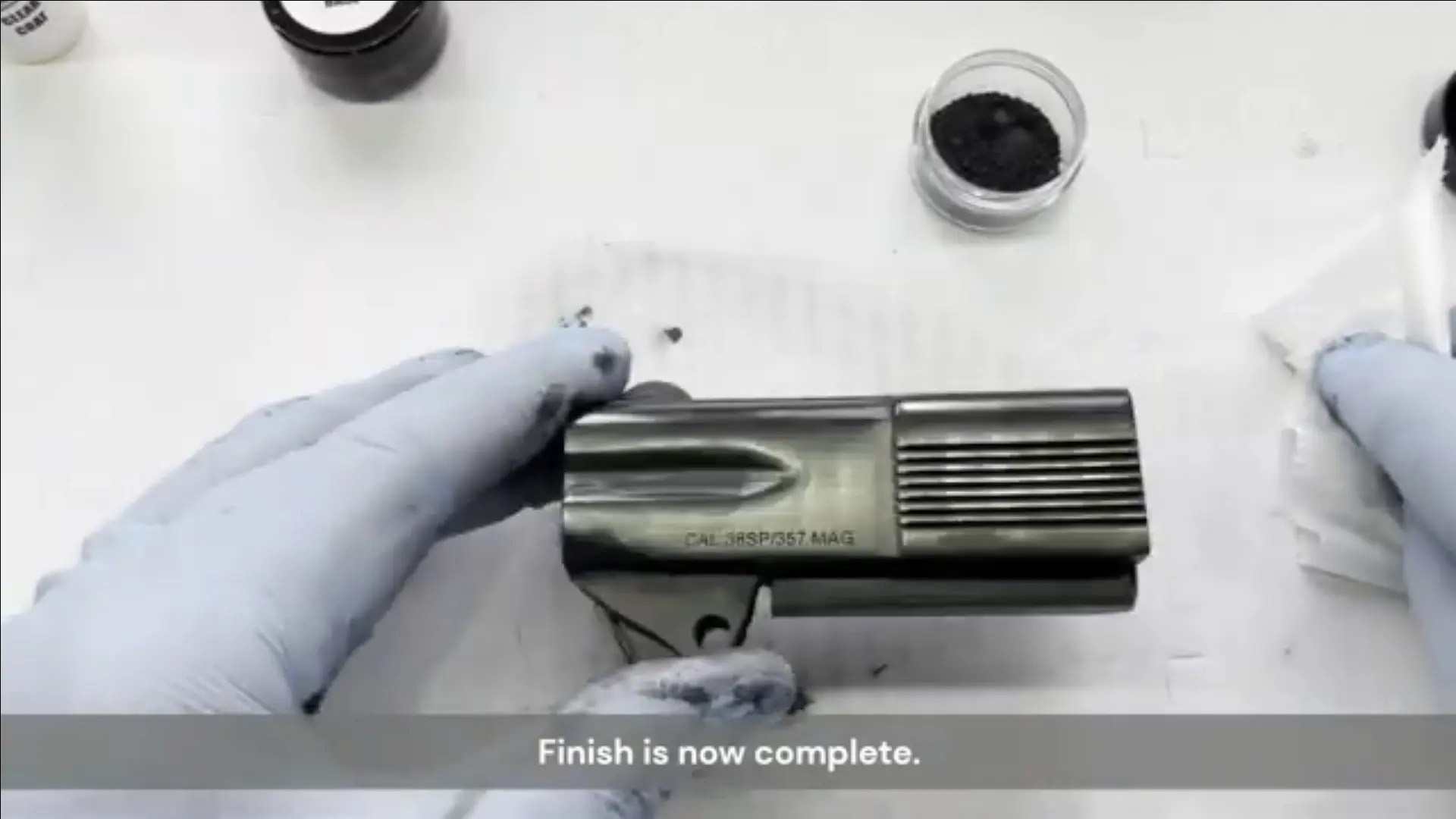

This example shows how good a finish you can achieve even with sub-optimal preparation.